Current position: Home > Solution > Sewage tank cap Back

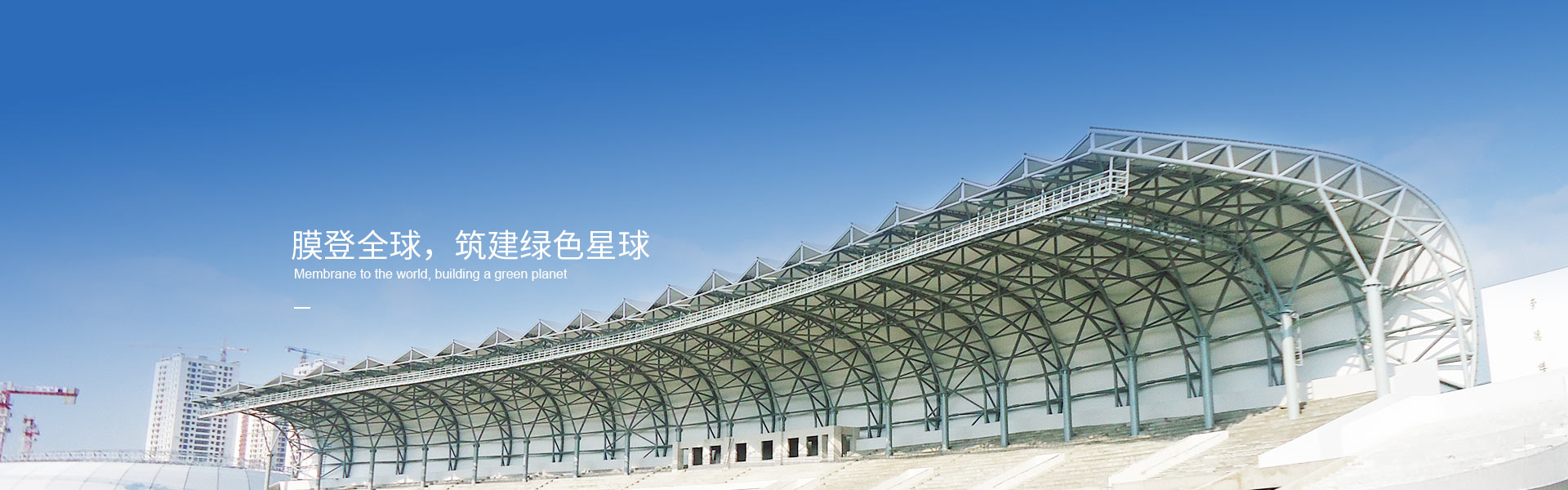

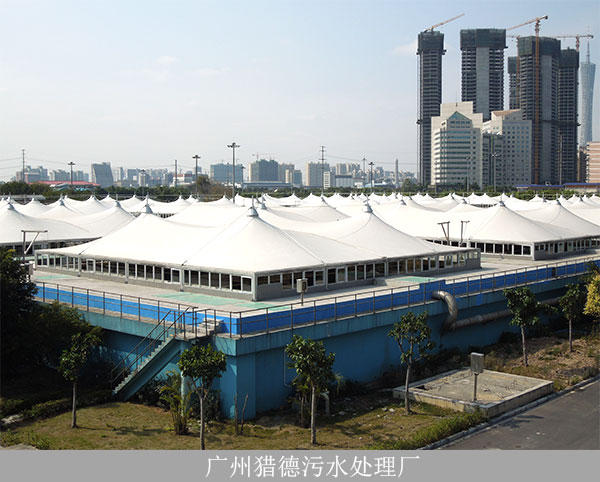

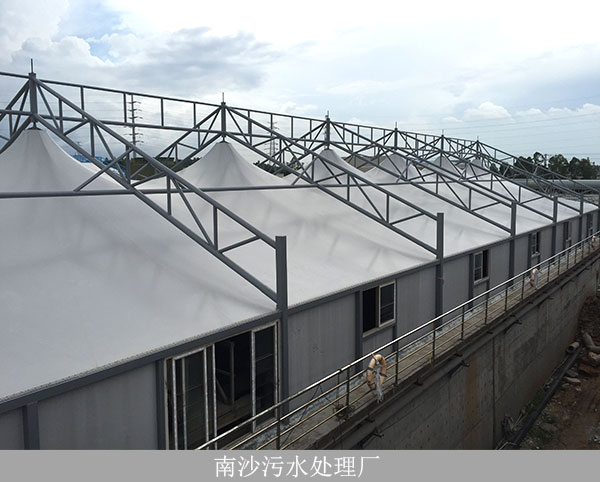

With the increasing attention of environmental protection, the odor gas produced by municipal sewage treatment plants in the process of sewage treatment has gradually become a problem that can not be ignored. In order to minimize the impact of sewage treatment plants on the surrounding environment, it is imperative to cover (cover) the structures of sewage treatment plants.

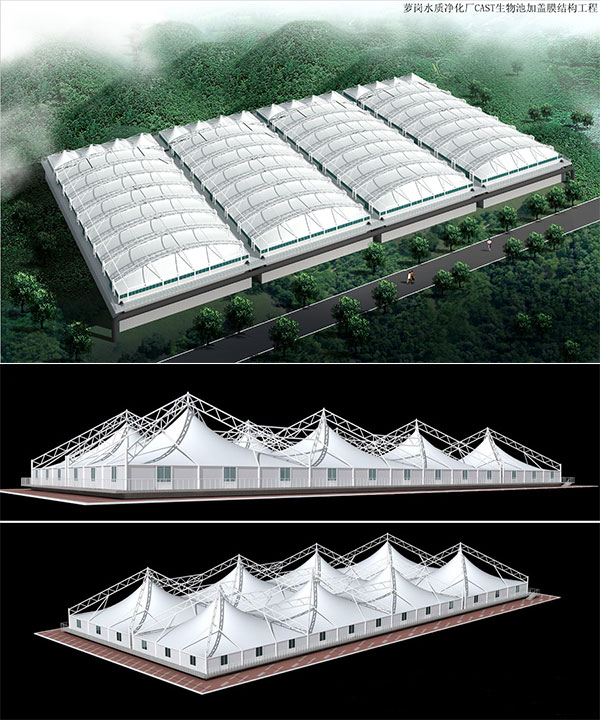

The effective method of deodorizing system for sewage pool is to cover and seal the sewage pool, and then breathe through the air inlet and outlet to pump the odorous gas on demand to the intelligence device for deodorizing treatment.

Odorous gases are fugitive and easily affect the surrounding environment. Therefore, the sealed collection of odorous gases is the premise of deodorization treatment.

Main applications: aquaculture farm, water treatment, garbage treatment plant, petrochemical tank, sewage tank, sedimentation tank, aeration tank, sugar factory, etc.

1、Steel support and suspension membrane structure: The exhaust gas is covered by anticorrosive film with strong anticorrosive ability, and the membrane is suspended outside the steel structure. This not only gives full play to the anticorrosive performance of the anticorrosive film, but also fundamentally solves the corrosion problem caused by the contact with corrosive gas of the steel structure, so the steel structure can be steel-bonded according to the ordinary building. The anticorrosive grade of the structure is designed, which has a service life of 50 years, exerts the performance of the steel structure and realizes the combination of the structure skeleton and the covering material.

2、Suitable for large-span pools: after special UV curing treatment and anti-mildew, anti-corrosion and anti-bacteria treatment, the membrane has excellent anti-corrosion performance, light weight, high tensile strength, and has great advantages for large-span structures.

3、Simple fabrication: steel support reverse suspension, steel structure fabrication and membrane fabrication are carried out in the factory, the quality is guaranteed.

4、Installation is fast: After the processed steel structure and membrane materials are transported to the site, they can be installed conveniently. They basically do not occupy the site, and the site installation time is very short. Especially for the old pool reconstruction project, the whole hoisting can be used without affecting the operation of the pool equipment.

5、Easy maintenance: Maintenance doors and access can be reserved on the side membrane to facilitate regular maintenance and inspection of equipment, without affecting the operation of sewage treatment ponds.

6、Good sealing performance: all the membranes are welded by hot melt welding, and the "secondary joint seal" of hot melt welding between the installed membranes ensures not only the sealing of the cover, but also the corrosion of the steel structure to the internal corrosive gas.

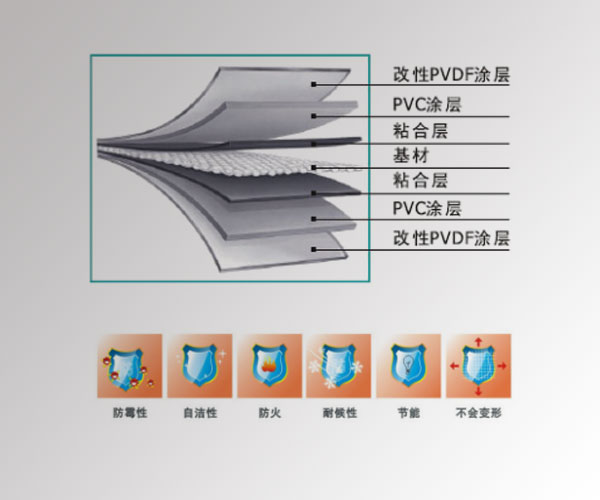

Anti-corrosion film material: It has the characteristics of high tensile strength, good flexibility, light and thin toughness, but also has the characteristics of tear resistance, wear resistance, oil resistance, non-toxic health, good air tightness and so on.

The outdoor durability of organic coatings can be improved by using advanced UV curing technology. The UV absorbent also acts as an external optical filter and prevents harmful sunlight radiation from entering the coating substrate. It can effectively improve the aging resistance of organic materials and maintain stable physical properties at high and low temperatures. It has chemical stability under acid and alkali conditions. The service life of materials under severe conditions such as strong corrosion, strong acid and alkali and salt fog has been greatly improved.

How about the price of membrane structure architecture?

In the service life of membrane structure architecture?

Membrane structure architecture later how to maintain?

What are the membrane material of membrane structure architecture?

The application and features of two kinds of membrane structure

Membrane material is introduced

Service Hotline0755 27809070

Shenzhen: 2nd floor Huizhou, Baoan Xixiang Baoyunda Logistics Research and Development Center, Shenzhen: 8th floor, Block B, Jinhaoyuan Building, Huiyang District, Huizhou City, Guangdong Province

Email: folan@sz1680.com

Copyright 2018 Shenzhen Folan Space Membrane Structure Co., Ltd. all rights reserved.

Guangdong ICP prepare No. 18128411 -1

Technical support: 国人在线 Disclaimer Website map

Sweep and pay attention to us.